Challenges of current TCN

The current conventional train communication networks (TCN) are facing several challenges to improve the service including the limitation of bandwidth and the limitation of integration. To provide both high quality entertainment video and IP surveillance video, there will be a huge requirement of bandwidth, which is the main restriction for conventional train communication networks. Conventional networks adopt different technologies with proprietary which result in unnecessary costs to integrate with each other.

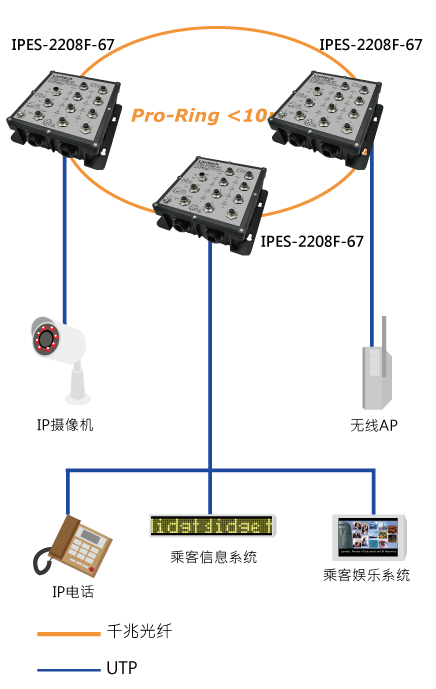

To construct a railway network with Ethernet infrastructures is the leading trend because it has several advantages. Because all the devices are connected with Ethernet, it is easier to integrate new systems and new applications. Another advantage is the ability of high-bandwidth. Ethernet backbones are able to provide a reliable network environment for implement of applications such as passenger entertainment systems and high-quality video surveillance applications. Connected with Ethernet cables, the installation and maintenance is much easier with less cost.

Harsh Environment

Different to the comfortable environment for passengers, the Ethernet devices in railway applications often operate in a narrow and harsh environment with unique requirements. Devices in rail train must be able to suffer under wide range temperature and humidity. Furthermore, severe air pollution, vibration, shock and EMC are commonly seen. That’s why Industrial Switches are needed to be certified by EN50155 standard.

The EN50155 standard is “Railways Applications Electronic Equipment Used on Rolling Stock”, which is commonly adopted by many countries and electronics manufacturers. Electronic equipment shall be designed and manufactured to meet the full performance specification requirement for the selected categories such as:

- Ambient temperature

According to diverse severe environments, there are four grades of operating temperature requirements defined by the EN50155 standard and are stated in the following table:

Class

|

Ambient temperature outside vehicle

|

Internal cabinet temperature

|

Internal cubicle over-temperature during 10 min

|

Air temperature surrounding the printed board assembly

空气温度 |

T1 |

-25°C to 40°C |

-25°C to 55°C |

70°C |

-25°C to 70°C |

T2 |

-40°C to 35°C |

-40°C to 55°C |

70°C |

-40°C to 70°C |

T3 |

-25°C to 45°C |

-25°C to 70°C |

85°C |

-25°C to 85°C |

TX |

-40°C to 50°C |

-40°C to 70°C |

85°C |

-40°C to 85°C |

EN50155 adopts testing methods and limitation according to EN 61373 - Railway applications - Rolling stock equipment - Shock and vibration tests. The standard ensures the equipment to be able to withstand vibrations and shocks and provides the specified useful life under service conditions. To satisfy the requirements, the equipment should be specifically designed with anti-vibration mounts and installed the electronic units completely.

EN50155 defines the relative humidity standard that equipment should follow: The equipment should be able to withstand 75 % of the average yearly relative humidity and 30 consecutive days with 95 % relative humidity in the year. IP67 enclosure is one of the best solutions, which provides rugged and waterproof protection to against moisture environments that may cause any malfunction or failure.

The equipment may be exposed in different locations where various pollutants are available, including oil mist, salt spray, conductive dust, sulphur dioxide. To ensure the durability, the equipment should have IP-rated enclosure to against the negative effects from these pollutants.

-

Electrical service conditions

To overcome the severity and provide the stable services in railway applications, EN50155 also defines several standards for electrical service conditions such as input voltage range, input voltage ripple, and input surges. Each category follows clear requirement. For example, the requirements of input voltage are listed below:

Input Voltage Requirements |

Nominal Input

|

Permanent input voltage range

|

Brownout 100ms (0.6xVnom)

/strong> |

Transient 1s (1.4xVnom)

|

24VDC |

16.8-30.0V |

14.4V |

33.6V |

37.5VDC |

26.2-47.0V |

22.5V |

52.5V |

48VDC |

33.6-60.0V |

28.8V |

67.2V |

72VDC |

50.4-90.0V |

43.2V |

100.8V |

96VDC |

67.2-120.0V |

57.6V |

134.4V |

110VDC |

77.0-137.5V |

66.0V |

154.0V |

Electromagnetic compatibility (EMC) is another main category of EN50155 standard. The equipment should be protected in order not to be negatively affected by conducted or radiated interference, which is referred to EN 50121-3-2 and should not emit radio frequency interference (RFI) that excess the level defined in EN 50121-3-2.

Lantech EN50155 series models provide IP-67 protection and M12 connectors with wide operating temperature from -40°C to 75°C for harsh operating environment in railway applications. The rugged and durable switches have long MTBF that ensure the network quality of video entertainment service and high quality video surveillance at the same time with Giga fiber ports. Besides hardware specifications, the powerful software features also ensure the management convenience.

|