In process / manufacturing automation applications, the most common structure consists of PLC, DCS, and SCADA. With PLC and DCS, managers are able to control equipments such as robotic arms and conveyors and transmit data to SCADA, where connects with database and then generate statistic data for monitoring the operating status but also for a better productivity. The network between these devices and software must be reliable and accurate.

No matter in which kind of industry, Industrial automation nowadays needs to be absolutely accurate because any interruption or delay may result in a huge amount of lost. For example, the assemble line of an automobile factory consist of many precise robotic arms. A few seconds interruption may result in a line of defective products without instant correction. Thus, in process / manufacturing automation applications, there is a huge need for Real Time protocols, which include ProfiNet by Siemens, EthernetIP by Rockwell, and ModBUS by Schneider. The Real Time protocols were developed by the need of PLC’s connecting with robotic arms, conveyor belts and other automation devices for process / manufacturing automation. This created the need for switches to be compatible with Real Time protocols. By collocating with Ethernet switches, managers are able to monitor the status, detect the failure, and solve the problem immediately.

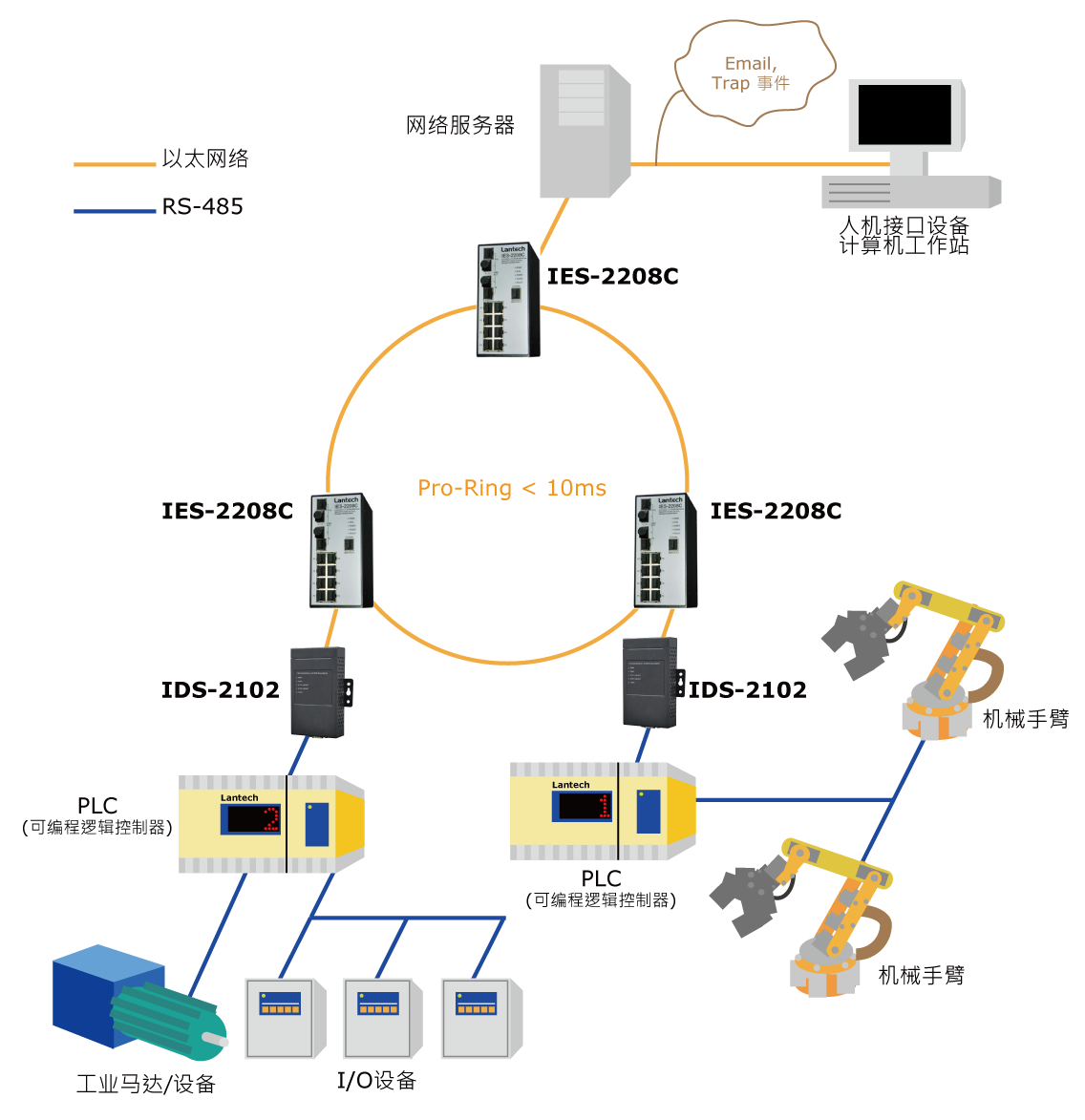

On the other hand, to satisfy the rapid changing industry environment, manufacturing process must have higher flexibility than before, which means a simpler and more convenient control system. Lantech industrial switches not only provide the Pro-Ring feature, which lower the recovery time of less than 10ms, but also support a variety of management functions such as web-browser, CLI, telnet, SNMP, and Lantech-View, a Windows based utility software.

To ensure long term reliability in critical industrial environments of process / manufacturing applications, each of the Lantech products has been tested extensively to meet Industrial EMI and EMC standards and undertaken to comply with free fall, shock and vibration stability test requirements. The IP30 metal housing also provides a robust protection to our products.

|